The FabPod is an acoustically tuned meeting room housed within an open-plan office at the RMIT Design Hub. The geometry of the FabPod derives from research we had previously conducted on the sound scattering properties of hyperboloids as part of the Responsive Acoustic Surface workshop (2011) – itself inspired by Gaudí’s use of hyperboloids. The FabPod’s form and materiality arose from a series of workshops in 2012 that investigated how to minimise the echo within a meeting room without creating an acoustically ‘dead’ space. By positioning hyperboloids to maximise sound scattering within the space, the FabPod has an unusually warm and diffuse acoustic. Walking inside, you can feel the FabPod in your ears.

The project was completed in March 2013, with the help of a large team (see credits at end). Nick Williams led the project along with the principle researchers: Brady Peters, John Cherrey, Jane Burry, Mark Burry, Alex Pena de Leon, and myself. Within this team I was responsible for establishing the geometric rules that defined the FabPod and creating the parametric models through which the FabPod was designed. These models had to deal with extremely intricate geometry while gracefully handling a number of material constraints, and they had to be fast enough and flexible enough to support the iterative design process that led to the FabPod. These models and the construction of the FabPod are detailed below.

(sketched in January 2011). At the time our construction system was unable to accommodate the geometric variation, so we instead chose to build the Responsive Acoustic Surface as a semi-circular wall – the concept reemerged two years later as the basis for the FabPod.](/img/1_sphere_circa_201101-ccxU-K_BSG-730w.jpeg)

One of my early concept models for the Responsive Acoustic Surface (sketched in January 2011). At the time our construction system was unable to accommodate the geometric variation, so we instead chose to build the Responsive Acoustic Surface as a semi-circular wall – the concept reemerged two years later as the basis for the FabPod.

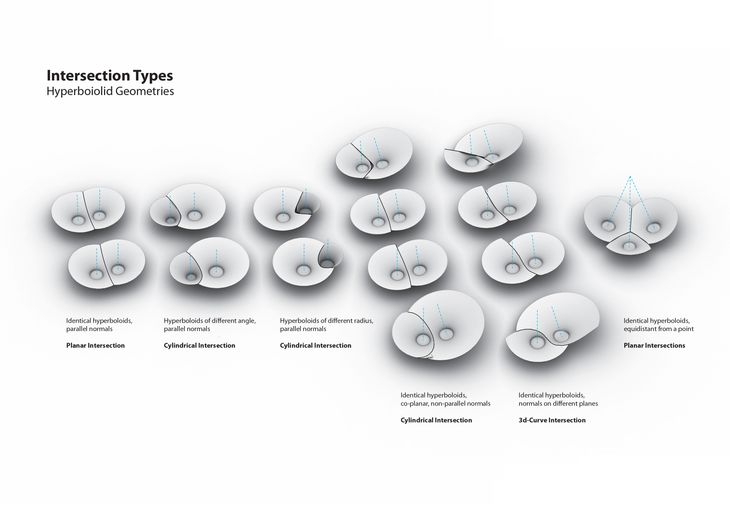

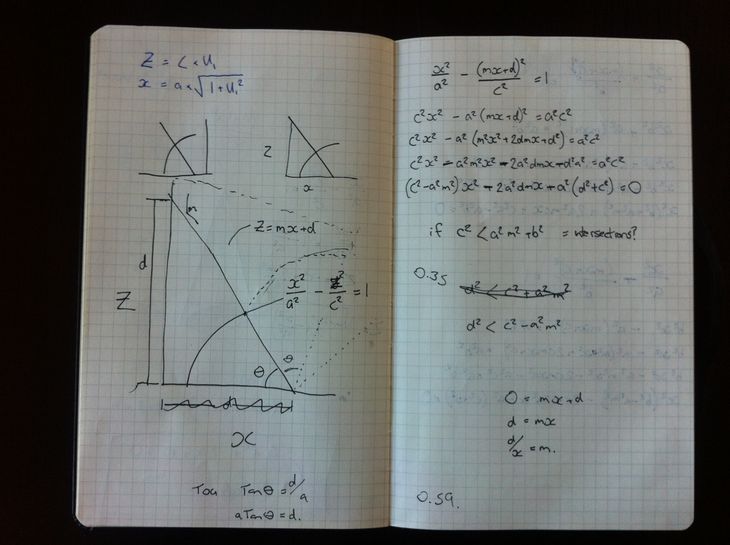

Geometric axioms I developed while looking for a set of rules that guaranteed planar intersections between hyperboloids.

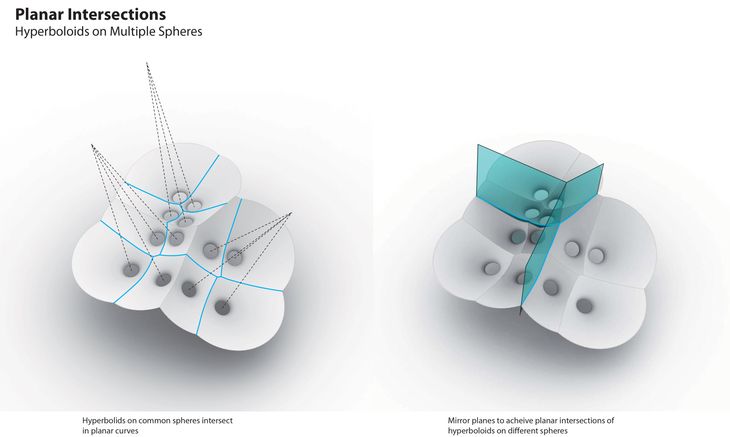

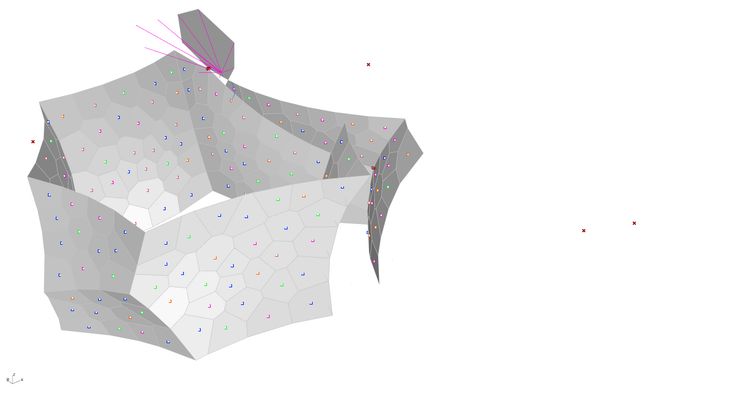

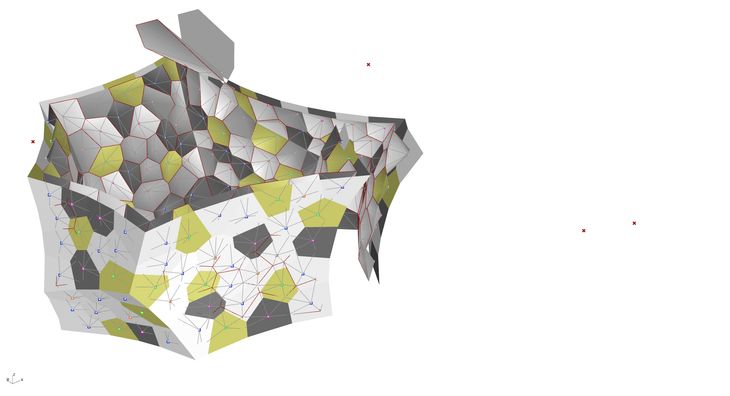

Diagram of geometric rules driving the FabPod. Essentially, all the hyperboloids are distributed on a sphere, pointing towards the sphere's centre. Where two spheres meet, the hyperboloids are mirrored over the plane of intersection. This insures the hyperboloids can be supported by a planar frame.

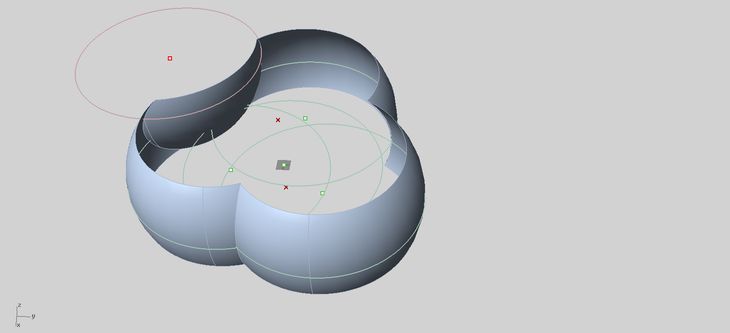

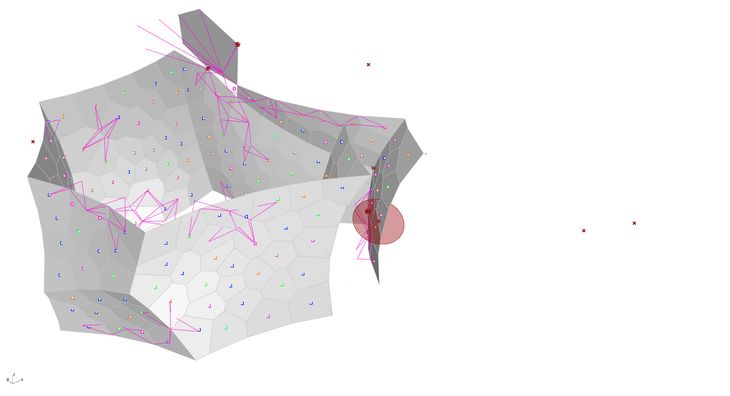

Parametric model I created to position the underlying spheres. For acoustic reasons, the final FabPod model only uses the negative spheres (one of which can be seen in the top left of this drawing).

.](/img/5_spherical_voronoi-KGbxuraEtp-730w.jpeg)

The spheres were then panelised using a spherical voronoi algorithm I developed. Download code here.

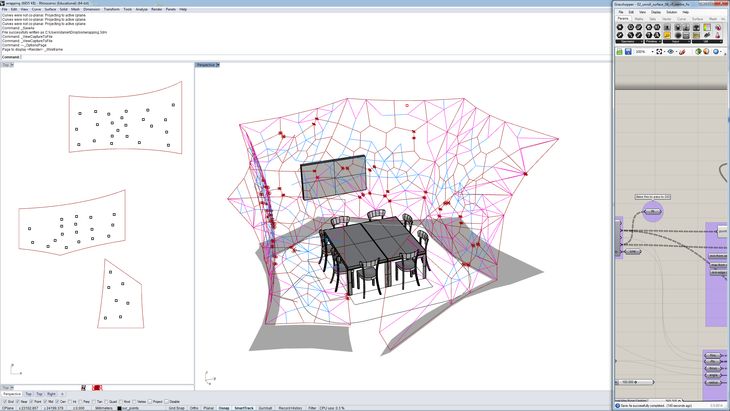

Left: The segments of the spheres are unrolled and the centre of the panels marked. Right: These are then projected back onto the surface to give the panel layout for the FabPod.

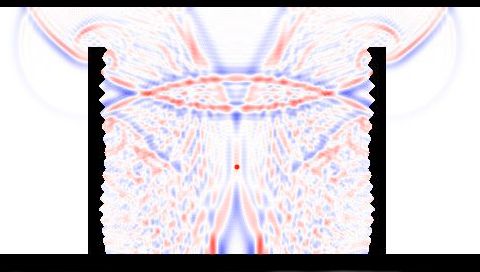

We then ran sound tests using software developed by Brady Peters (shown), Pachyderm, and Odeon – in combination with physical sound tests and our previous research on the Responsive Acoustic Surface. Based on these tests, we then developed new iterations of the FabPod.

Manufacturing tolerances were added to the parametric model. Here the pink lines highlight hyperboloids that are too close together, have too many sides, have sides that were too short to manufacture, or that are too large to manufacture.

After refining the panel layout, this is the final geometry. The colours in the panel centres represent the materials of the hyperboloids.

A challenge we faced in the Responsive Acoustic Surface was finding the intersections between hyperboloids. We tried every intersection algorithm in every software but they were all too slow to support iterative development. This is my working for an analytic algorithm that was one thousand times faster than the next best algorithms – turning something that previously took minutes into something that took less than a second.

The final FabPod form, with all the correct intersections and materials.

The frame was cut on a five axis router. Photo by Nick Williams.

The frames of 180 bricks assembled.

The bricks ready for stacking. Photo by Nick Williams.

Final assembly took roughly a week.

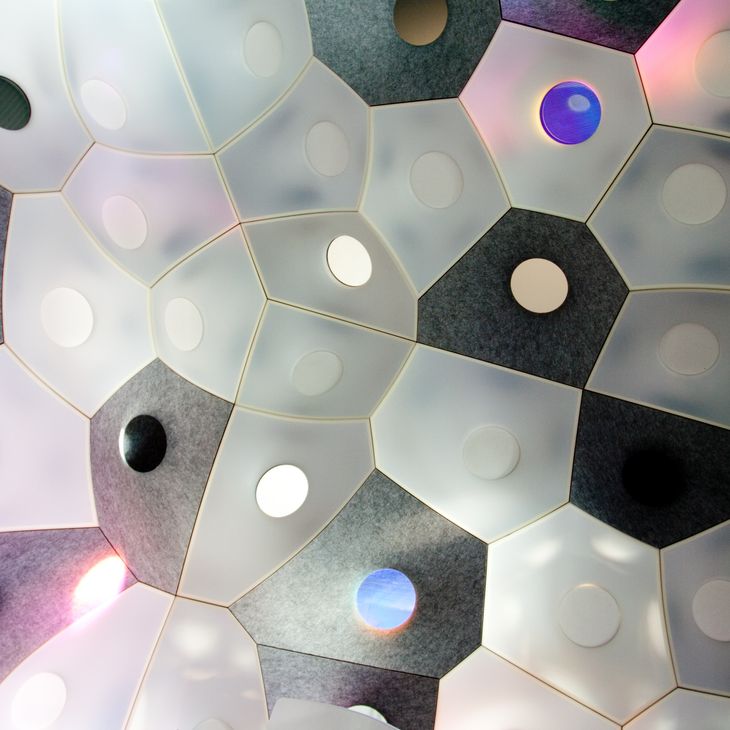

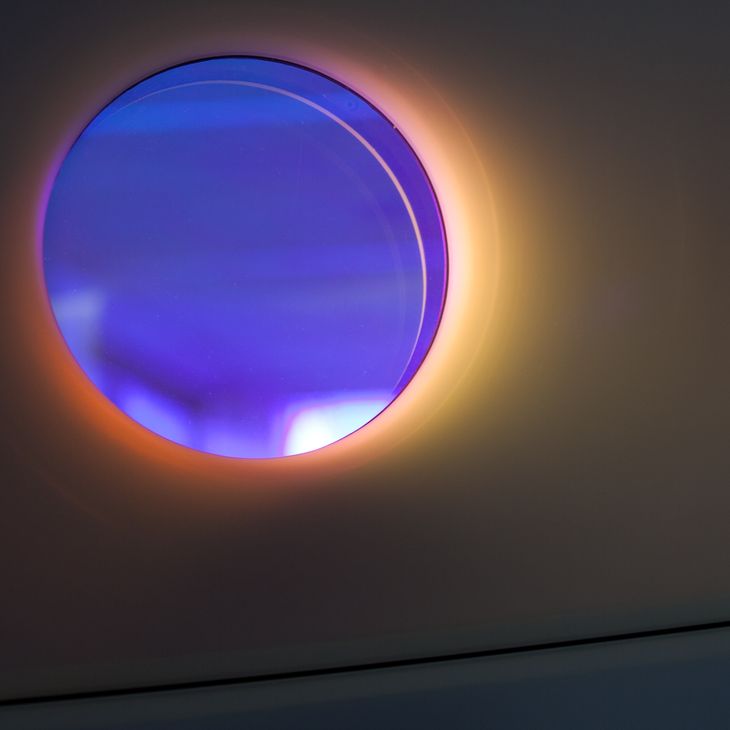

Photograph by John Gollings.

Photograph by John Gollings.

Photograph by John Gollings.

Photograph by John Gollings.

Make sure you view this photo full sized.

Visit the FabPod

The FabPod is located on Level 9 of the RMIT Design Hub (building 100), corner of Swanston and Victoria Street, Melbourne, Australia.

Project Credits

Project Researchers: Nick Williams, Brady Peters, John Cherrey, Jane Burry, Mark Burry, Alex Pena de Leon, Daniel Davis.

Research Partners: Memko Pty Ltd, Felicetti Pty Ltd, School of Electrical & Computer Science, RMIT University.

Project Support: SIAL, RMIT University; CITA, Royal Danish Academy of Fine Arts; Design Research Institute, RMIT University; Property Services Group, RMIT University; The Independents' Group, RMIT University; The Australian Research Council through funding for the Discover grant “Challenging the Inflexibility of the the Flexible Digital Model”.

Project Sponsors: Woven Image Echopanel, The Laminex Group, Sapphire Anodising.

Prototyping Research Assistants: Nathan Crowe, Dharman Gersch, Arif Mohktar, Costas Georges, Andim Taip, Marina Savochina.

Prototyping Support: Andrew Miller, Michael Wilson, Andrew Thompson, Brad Marmion, Kevin O'Connor